THE TURBOROTOR

The functionality of the TurboRotor is based on turbulent airflow within the grinding zone, generated at the shear edges of the grinding tools. In the micro-air vortices, particles change both their direction and speed in extremely short time intervals. This increases the likelihood of particle comminution through mutual collisions. Throughout the entire process, the particles remain dispersed in the air.

Advantages of the TurboRotor

The TurboRotor is ideally suited for the gentle grinding of temperature-sensitive materials as well as substances with low melting or softening points.

Comminution Principle

In the TurboRotor, the material to be ground is subjected to the following stress mechanisms, depending on its material behavior:

Grinding and Drying

By combining the TurboRotor with a heat generator to warm the process air, it can be used as a grinding dryer without structural modifications. As the material is simultaneously ground during the drying process, its surface area increases rapidly. This allows moisture, even that deeply bound within the grain, to migrate to the surface during comminution, where it can easily evaporate.

Foodstuffs such as proteins, starch, starch derivatives, and other heat-sensitive materials can be gently ground and dried simultaneously at low air outlet temperatures, preserving their quality.

The TurboRotor can be divided into three sections:

Material Discharge

- For the separation of coarse particles

Grinding Zone

- Various grinding path profiles available

- Variable number and geometry of grinding tools, with infinitely adjustable rotor speed

- Variable retention time and turbulence for high evaporation performance

Material Inlet

- Introduction of material into the airflow or via a feed screw into the grinding zone

- Homogenization and uniform distribution before entering the grinding zone

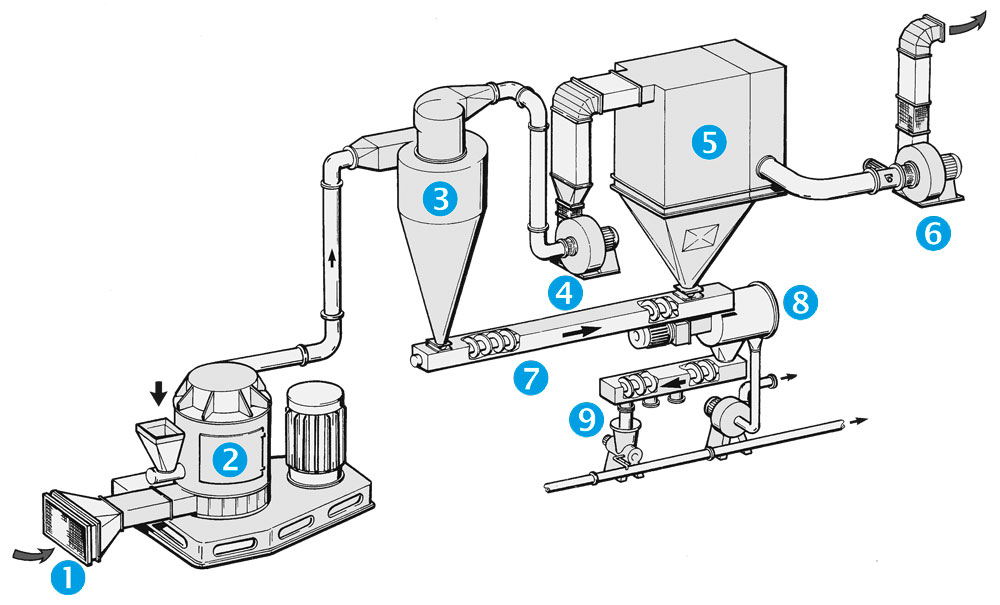

Components

- Heat exchanger for cooling or heating the grinding air

- Micro-vortex mill with load-dependent dosing

- High-performance HFA cyclone for pre-separation

- High-performance fan with high total pressure

- High-performance bag filter with pneumatic low-pressure cleaning

- High-performance fan for volumetric flow control

- Collection screw

- Vortex flow sifter for defined particle size limitation

- Distribution screw for bagging or pneumatic transport

Sizes of the TurboRotor

The product-contacting parts can be manufactured in various materials, tailored to the requirements of the products to be processed. For the processing of products whose parameters necessitate the use of safety equipment, compliance with ATEX 94/9/EC is ensured.

| Size | Drivemotor [kW] |

Speed [upm] |

Air volume flow [m³/h] |

|---|---|---|---|

| G-35 | 7,5 – 18 | 4000 – 8000 | 800 |

| G-55 | 15 – 55 | 1800 – 3600 | 2000 |

| G-90 | 45 – 110 | 1350 – 2500 | 5000 |

| G-130 | 90 – 200 | 1100 – 1700 | 8000 |

| G-150 | 132 – 315 | 900 – 1450 | 15000 |

| G-180 | 200 – 450 | 800 – 1200 | 25000 |

| G-200 | 315 – 630 | 650 – 1000 | 50000 |